Single Operator Iron Worker Machines (SOIWMs) are a cutting edge device that can be made use of for cutting, punching and also flexing metal materials. They offer an efficient method to do the job with simply one operator! With such machines, it'' s no longer essential to use several drivers when utilizing other kinds of steel working tools. SOIWM ' s are unbelievably versatile as well as can quickly take on all sorts of jobs from easy constructions to complicated layouts.

In addition, they'' re additionally very risk-free to make use of! Thanks to their structured layout which features safety and security guards that avoid any possible mishaps or injuries. Furthermore, these machines come with built-in sensors and alarm systems that signal the operator if something is wrong with the equipment. This provides added assurance and also assurance while operating single operator iron worker machines.

Despite its numerous benefits, there are still some things you ought to consider before buying a single operator iron worker equipment. Firstly, these machines require normal maintainance in order to keep them running efficiently. Secondly, they usually require specialized training prior to being run safely as well as properly by a bachelor. Finally, it is very important to pick a reliable version as not all designs give the exact same degree of performance or features.

Generally, single operator iron worker machines can provide numerous benefits in terms of performance as well as safety for metal functioning jobs; nevertheless, proper study must be carried out beforehand worrying their capabilities as well as upkeep needs so that their financial investment will certainly be worth it in the long run! Consequently, if you think this sort of equipment can profit your business procedures after that wear'' t hesitate - proceed and also make the purchase!

Utilizing a single operator iron worker maker supplies several advantages. Firstly, it is cost-efficient as it needs little labor compared to various other machines. This implies that organizations can conserve cash which they would certainly have otherwise invested in even more staff members! Additionally, it is easy to make use of as well as doesn'' t require any special training or qualification. In addition, the maker'' s portable size makes it excellent for small-scale markets with minimal room availability. Additionally, its accurate cuts provide superior outcomes than manual reducing approaches which frequently results in wastefulness because of errors.

An additional benefit of utilizing a single operator iron worker equipment is its security attributes such as guards as well as sensing units that lower the danger of mishaps on the job floor. Furthermore, these machines can faster production prices than manual labour which assists increase performance. Also, their sturdiness guarantees that they last much longer and require minimal maintenance prices with time. Lastly, they offer higher precision for precision jobs like welding as well as boring leading to remarkable top quality items!

To summarize, using a single operator iron worker device has several perks - from cost-effectiveness to enhanced security as well as boosted accuracy of work - making it a very useful property for organizations across numerous sectors!

Single operator iron worker machines are a sort of machinery made use of for numerous metal manufacture processes. They come in various types as well as sizes, supplying a variety of abilities that can be utilized to fulfill the requirements of any type of task. From small manual devices to big automated systems, there is an iron worker device offered to fit every budget and application.

Some examples of single operator iron worker machines consist of guillotine shears, plate punches, angle cuts, press brakes, beam of light cutters as well as notchers. These machines are typically seen in manufacturing plants where they are used for reducing or developing sheet metal elements such as doors, frames as well as other structural components. Guillotine shears utilize a strong blade that can cut through thick sheets of steel easily while plate punches supply precise hole making capacities. Angle cuts give specific corner bends while press brakes can bend flat product right into tilted forms with accuracy. Beam of light cutters and notchers permit even complicated shapes to be developed from strong stock rapidly and precisely.

In addition to these kinds of conventional single operator iron worker machines, some makers also provide custom-made designed remedies customized particularly for special applications or procedures. Numerous contemporary models also include advanced safety and security functions such as automated shut-off buttons when overloads happen or emergency stop buttons for included security during procedure. This guarantees operators remain safe while dealing with these powerful devices!

On the whole, single operator ironworker machines offer customers with reliable performance and optimum convenience for virtually any type of metalworking job possible! With a variety of dimensions as well as abilities readily available, these powerful devices can assist take your service' ' efficiency to the next level. Transition expression: To sum it up ... No matter what you require performed in terms of metalworking operations, there'' s sure to be a suitable single operator ironworker equipment around prepared to get the job done right!

Selecting the ideal single operator Iron Worker Machine for your needs can appear like a complicated job. There are numerous variables to think about; dimension, price, as well as features simply among others! Nonetheless, with a little research you can find the ideal equipment to fit your requirements.

First (1 ), it'' s vital to determine what kind of tasks you mean to do and also exactly how commonly they will be done. For example, if you need large construction or automation after that larger machines would be better. On the various other hand, if you plan on doing smaller projects after that a smaller sized design may be enough. On top of that, if you'' re operating in a location with restricted room then choosing an equipment that is small may be crucial.

Following (2 ), consider the spending plan offered for acquiring the iron worker equipment. It'' s best to choose an ideal cost variety before searching so that you don'' t obtain excessively excited in any way of the bells and also whistles some versions offer but can not afford them. In addition, ensure that any type of added costs such as delivery and also setup are factored into the final acquisition price also.

Also (3 ), seek features that will certainly make your job easier and also quicker such as adjustable blades, swivel stands, as well as automated controls. These features can save time when reducing or punching via metal which makes manufacturing much faster as well as much more effective! Additionally, safety attributes need to not be overlooked either - make sure that any type of design chosen has actually guards set up to shield versus crashes or injury while operating the equipment.

To conclude (4 ), selecting the ideal single operator iron worker machine for your requirements doesn'' t have to be hard - just examine what tasks need finishing first of all and consider budget restrictions second of all while investigating versions thirdly that deal additional features furthermore such as improved safety and security systems fifthly. With this strategy in mind sixthly, locating the most effective iron worker equipment shouldn'' t be as well hard! Be sure to research your options before purchasing! However, we would certainly constantly recommend the machines that Gulf States Saw & & Equipment needs to provide.

Single operator iron worker machines are effective tools for metalworking tasks. Nonetheless, it'' s important to exercise proper treatment as well as upkeep to keep them in leading problem! To do this, one must make sure the equipment is on a regular basis oiled and tidy. Make certain all parts are secured as well as tightened effectively. Additionally, regularly check for any type of indicators of wear or damage. If any problems are found, repair/replace the damaged element promptly!

Likewise, it'' s necessary to use the right security gear when running an iron worker maker. Using a face shield as well as durable gloves will certainly shield you from flying particles and stimulates. Furthermore, always read the instruction manual very carefully prior to beginning a task - this will certainly assist you stay secure while utilizing the maker!

Finally, never overlook regular precautionary maintenance on your iron worker maker - it'' s essential for guaranteeing its durability as well as efficiency! Check all components like equipments, bearings and so on, a minimum of yearly; change worn out parts quickly. Moreover, store your equipment in a completely dry place away from extreme temperature levels as well as direct sunlight. This way you can anticipate years of trusted solution from your single operator iron worker maker!

Finally, with some simple safety measures as well as routine maintenance ideas you can ensure your ironworker functions successfully as well as safely at all times. Simply keep in mind to always follow the supplier'' s directions for finest outcomes! You can check out some of these machines on the Gulf States Saw & & Machine web site

Utilizing single operator iron worker machines can be dangerous, and also there are some usual safety considerations to remember. To begin with, it is very important to always wear safety equipment consisting of eye-wear when running the maker! It'' s additionally crucial not to utilize any kind of loose garments or jewelry that might obtain captured in the relocating equipment. And also constantly remember to turn off power before making modifications or repair work on the machine.

Also, see to it you check out as well as comprehend all instrutions very carefully before beginning operation. Never ever try to run an equipment without correct training and also guidance! In addition, take routine breaks while utilizing the devices as this can help reduce exhaustion and also rise focus degrees. Finally, guarantee that all guards remain in place and also functioning appropriately in any way times, this consists of both foot pedals.

All-in-all, dealing with a single operator iron worker calls for additional care for your own safety and security as well as those around you. Taking some time to thoroughly review safety guidelines and also methods can go a long way in the direction of maintaining everyone secure from harm! With these simple actions taken into consideration, drivers of these machines ought to have a delightful experience utilizing their devices.

Troubleshooting single operator iron worker machines can be a difficult task! The good news is, there are some common issues that can conveniently be repaired. First of all, if the device is not working at all, inspect the source of power and make certain it'' s plugged in appropriately. Likewise, look for any type of blown fuses or tripped breakers. If neither of these services suffice, it may be time to call an electrician!

Secondarily, if you experience slippage while cutting steel with your device, then you ought to check to see if the blade is properly lined up as well as lubricated. It could just require a bit of tightening or lubrication to get it running smoothly once more! Furthermore, make certain that all screws and also screws are tightened up adequately. If this does not function, think about replacing the blade completely.

Ultimately, if your device isn'' t feeding material effectively through its blades or punches then inspect if any kind of parts are worn or blocked by particles. It might likewise assist to change the feed rate so that it'' s slower than what it was formerly set at. Furthermore, when loading material right into the maker see to it that all parts are firmly secured in position before starting up the operation.

In conclusion, troubleshooting single operator iron worker machines can be difficult yet with some patience and a keen eye for detail you'' ll quickly have them operating like new again!

Single operator iron worker machines are a highly helpful tool in several commercial applications. They are not just save time and money, however they likewise assist to reduce the threat of injury or accidents. Nonetheless, because of their intricacy as well as size, it'' s important to take correct safety and security preventative measures when using this type of equipment. First of all, operators should always wear proper protective equipment such as safety glasses and gloves to safeguard against flying debris and also sparks. Additionally, customers should stick strictly to the producer'' s guidelines in order to avoid any type of unnecessary dangers or injury.

However that isn'' t all! Operators must also bear in mind where the maker is located in regard to other individuals - particularly kids - that might neighbor. At GSS Machinery, we understand the importance of reliable equipment in the metal fabrication industry. Our Single Operator Iron Worker Machines . Furthermore, if something fails with the device, users must have the capacity to shut it down quickly and also safely till fixings can be made. All these steps will certainly make certain that single operator iron workers can proceed being a very useful property for industry without unneeded risk! In conclusion, single operator iron worker machines are extremely beneficial tools when made use of properly and also safely; however, individuals have to comply with all needed preventative measures for their very own defense in addition to those around them! So why not provide it a shot? You won'' t regret it! Head on to the Gulf States Saw & & Machine website currently.

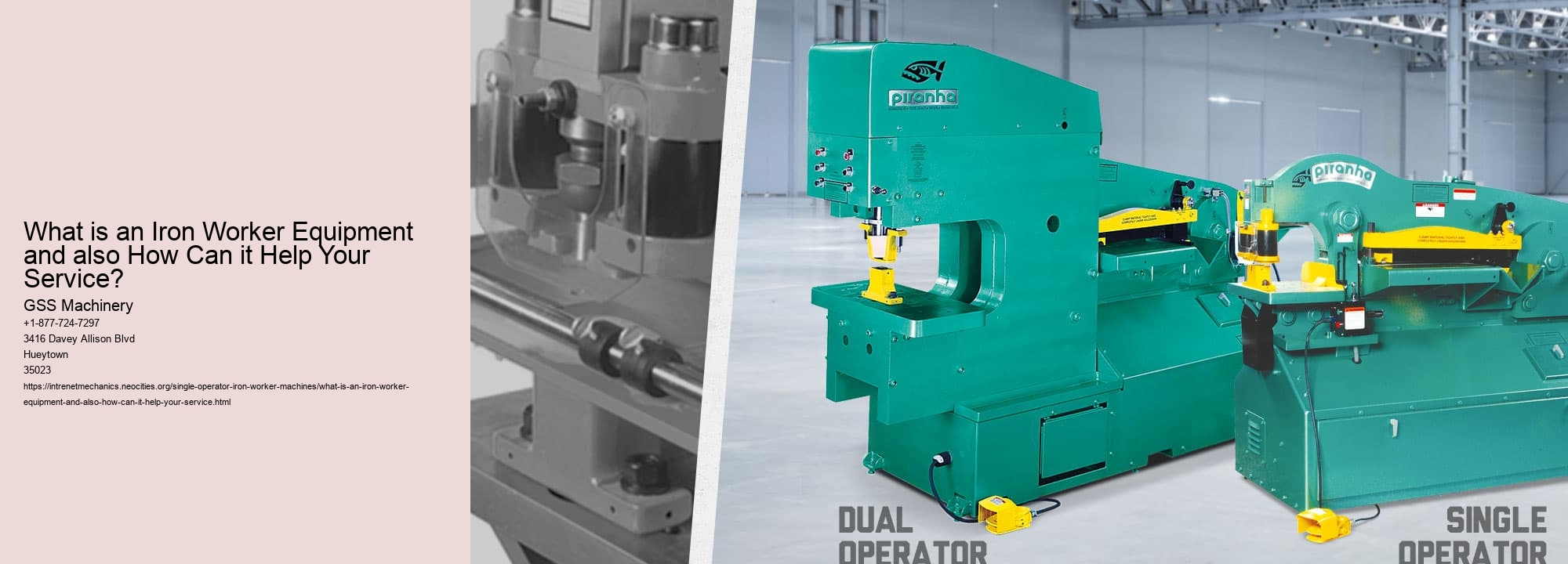

Scotchman Ironworkers come in models for single and dual operators. Punch Station. This is one the most useful tools that can be found in any ironworker. Flat Bar Shear. ... Angle Shear. ... Notcher. ... Tool Table Workstation for Component Tools. Dual Operator System.

Ironworkers can be classified into three types: structural, ornamental, and reinforcing. Reinforcing ironworker. Structural ironworker. Ornamental ironworker.

Ironworkers can also work with composite or wood materials or precast walls. Reinforcing steel and rebar workers place and secure steel mesh or bars in concrete forms to reinforce them. Rod busters are often used to describe those who work with reinforcing iron (rebar), referring to the rods of rebar.

San Francisco, CA is the highest paying city for ironworkers in the United States. $43.82 an hour 5 salaries reported. $51.60 per hour 10 salaries reported. Seattle, WA. Seattle, WA. 6 salaries reported. Decatur, AL. Decatur, AL. 5 salaries reported. Nashville, TN. 25.38 dollars per hour. 8 salaries reported. See more nearby cities.

In the United States, the average salary for Iron Workers Locals 40, 361 and 417 Health Fund amounts to $3,333.771.

Ironworkers were known as "cowboys of the sky." These young men, who were independent and daring, became husbands, and provided for their families. They realized that by uniting together, they could make their voices heard and stronger.

They are both highly skilled professions, but their skill sets and tools and materials differ. Ironwork is typically more structural, while sheet metal fabrication tends to be more functional. Both types of metal fabricators use a wide range of metals and machinery.

Ironworkers need to be able tie rebar quickly and accurately. Physical stamina. Ironworkers and Steelworkers need to have physical endurance, as they spend many hours a day doing physically demanding tasks such as moving rebar. Physical strength.

Some construction occupations are more prone to death from falls. Ironworkers, for example, are more likely to die from falls than any other occupation (38.7 deaths per 100,000 full-time employees).

Balance, hand-eye co-ordination and physical strength are three soft skills that an iron worker should have.

Ironworkers often have to tie off steel structures at their level.

When the personnel is immobile, they must be tied off. Before any work exceeding 30 feet, temporary decking is installed as interior fall protection.

Reinforce structures by placing steel bars in concrete forms. Tie rebars together using tie wire. Install the post-tensioning cables (cables), along with reinforcing steel, in the concrete forms.

The Best States for an Iron Worker West Virginia was rated the best in the country for iron workers. Anchorage had the highest earnings in this field.

Iron workers are on average 41 years of age.

The innovative and high-quality features of the Piranha ironworker machine are a great benefit to metal fabricators. Each Piranha offers quality work, reduced set-up times, adaptability, and versatility with a variety of tools, factory engineering, and support.

Ironworkers lay and fabricate the structural steel frame of pre-engineered buildings, stadiums and bridges. They also cut and weld steel, read blueprints and work with concrete reinforcement steel bars.

Iron Workers Memorial Bridge / Location

Cons of being an ironworker Heavy lifting, climbing and working in awkward postures can cause injuries if safety precautions aren't taken. Weather Conditions: Ironworkers are often required to work outdoors in all kinds of weather, including extreme heat and cold, rain and snow.

Iron and steel workers die on average 47 times per 100,000. Workers are at high risk for severe injuries despite stricter federal safety regulations and the use safety devices like nets and scaffolds.

Ironworker machines can punch, shear and notch holes in steel plates and profiles. Now, the name is used to describe a whole class of machines. (Made by at least 12 brands including Edwards). The name of the brand has been genericized.

We have also mentioned that ironworkers work hard in difficult conditions. Construction trades are no doubt hard work. The type of work can be very hard on the body. All the crouching and climbing, as well as carrying and clenching of tools, can wear down a body.

The Work of an Ironworker They spend the majority of their time cutting, bending and connecting heavy materials, as well as in awkward positions such as stooping. Ironworkers work outside, but only in good weather. Ironworkers usually work full-time schedules.

The ironworkers who work in this field are well aware of Subpart R and that they do not need to tie off until working at a height of 15 feet (or 30 feet). They are actually trained in this rule, which is a requirement of OSHA's Subpart R.

Ironworkers not only build buildings, which can be huge, but also bridges and rides for amusement parks.

The employee will use the harness if he likes it. Remember that it's very difficult for a worker to attach a harness to rigging points if they are not wearing one. OSHA mandates that ironworkers be protected from falling.

Ironworker Riggers load, unload and move machinery, structural steel and curtain walls. They also do any other work or materials that fall under their jurisdiction. The work can be done by using power hoists or cranes.

San Francisco, CA is the highest paying city for ironworkers in the United States. $43.82 an hour 5 salaries reported. $51.60 per hour 10 salaries reported. Seattle, WA. Seattle, WA. 6 salaries reported. Decatur, AL. Decatur, AL. 5 salaries reported. Nashville, TN. 25.38 dollars per hour. 8 salaries reported. See more nearby cities.

In the United States, the average salary for Iron Workers Locals 40, 361 and 417 Health Fund amounts to $3,333.771.

On September 28, 1990, the International Association of Bridge, Structural and Ornamental Iron Workers chartered the Local One Retirees Club. We have worked hard to represent Retired Local One ironworkers in a variety of areas over the years. They deserve to be treated with respect and dignity.

Most workers earn $8 an hour. Most of these workers do not have health insurance or retirement benefits.

The average wage of Ironworkers Local 5 is $76 per hour. Hourly wages can range from $66 up to $88.

What am I earning? Apprentices in the first period start at 60% of the journeyman wage, or $25.96/hr. The average wage for journeymen hired by participating employers is $43.27/hr.

What is the average salary of a Journeyman Ironworker in the United States at Iron Workers Local 25? According to our data, the ideal compensation range for a Journeyman Ironworker in Iron Workers Local 25 appears to be between $39,294 - $46,355, and an average salary is $40,564.

Union Ironworkers 550 Salary Questions How much is Union Ironworkers 550 paid per hour? Union Ironworkers Local 500 pays an average of $32 an hour for undefined.

BHR Ironworker 33,83 $ Apprentice Percent First 6 Months 16,91 $ 2nd 6 months 18,61

Ironworkers were known as "cowboys of the sky." These young men, who were independent and daring, became husbands, and provided for their families. They realized that by uniting together, they could make their voices heard and stronger.

Rodbusters, also known as reinforcing ironworkers, use reinforcing bar to build structures according to a specific design. Reinforcing Ironworkers tie reinforcing bar together using tie wire to assemble structures.

On June 17, 1994, the bridge was renamed "Ironworkers Memorial Second Narrows Crossing", in honour of the 18 workers who perished during the collapse. Also, one rescue diver, and four other construction workers also died.

Iron workers are on average 41 years of age.

We have also mentioned that ironworkers work hard in difficult conditions. Construction trades are no doubt hard work. The type of work can be very hard on the body. All the crouching and climbing, as well as carrying and clenching of tools, can wear down a body.

Some construction occupations are more prone to death from falls. Ironworkers, for example, are more likely to die from falls than any other construction occupation (38.7 deaths per 100,000 full-time employees).

Scotchman Ironworkers come in models for single and dual operators. Punch Station. This is one the most useful tools that can be found in any ironworker. Flat Bar Shear. ... Angle Shear. ... Notcher. ... Tool Table Workstation for Component Tools. Dual Operator System.

Ironworkers are required to use many different tools. The tools used by ironworkers include wrenches and ratchets. They also use pliers, magnetic squares (squares with magnets), pliers for pulling wire, porter bolt cutters, levels, hard hats, impact sockets, lanyards tool tethers, safety vests etc.

The ironworkers who work in this field are well aware of Subpart R and that they do not need to tie off until working at a height of 15 feet (or 30 feet). They are actually trained in this rule, which is a requirement of OSHA's Subpart R.

Average annual salary for ironworkers is $74,210.

Cons of being an ironworker Heavy lifting, climbing and working in awkward postures can cause injuries if safety precautions aren't taken. Weather Conditions: Ironworkers are often required to work outdoors in all kinds of weather, including extreme heat and cold, rain and snow.

Ironwork Hazards They climb to high places and use welding equipment above them for long periods of time. Ironworks also pose other hazards, such as the possibility of burns from metal shavings or sparks.

These day workers also cannot be afraid of heights. This is because projects such as skyscrapers or bridges often require them to work at very high altitudes.

Ironworkers not only build buildings, which can be huge, but also bridges and rides for amusement parks.

San Francisco, CA is the highest paying city for ironworkers in the United States. $43.82 an hour 5 salaries reported. $51.60 per hour 10 salaries reported. Seattle, WA. Seattle, WA. 6 salaries reported. Decatur, AL. Decatur, AL. 5 salaries reported. Nashville, TN. 25.38 dollars per hour. 8 salaries reported. See more nearby cities.

Ironworkers install structural iron and steel and reinforce it to support and form bridges, roads and other structures.

Organise yourself to earn more. Health insurance. Life insurance. An annuity or defined benefit pension, not just a 401k. A grievance process so that you can be heard if there is a dispute with your employer.

It was thought that Hawaii's climate made it difficult to wear business attire, so this would benefit both workers and the garment industry.

The wedge boot's wide, flat sole helps ironworkers to evenly distribute their weight, which prevents them from losing their balance or slipping. They are also comfortable. Ironworkers will not have sore feet after a long day of work.

The question is: Which boots should I choose? According to OSHA regulations, you may need steel-toed boots for your work boots. However, most people prefer to wear non-safety-toed boots. The decision will depend on what materials you use. A steel toe boot will not provide additional protection if your materials exceed the weight rating.

Balance, hand-eye co-ordination and physical strength are three of the most important soft skills that an iron worker needs.

Iron Worker duties include welding beams, ensuring safety, preparing construction sites, reducing the damage to iron paint treatments, and using tools such as torches and an arc welder.

Ironworkers were known as "cowboys of the sky." These young men, who were independent and daring, became husbands, and provided for their families. They realized that by uniting together, they could make their voices heard and stronger.

Iron and steel structural and reinforcing components are essential to buildings, bridges and roads. Although the main metal used in this work, steel, is often referred to as ironworkers and erectors.

Ironworkers were once called "cowboys of the sky" when they first started out. These independent, daring men persevered despite the dangers of their work. Ironworkers in those early years rarely survived ten years without suffering a serious injury or death.

Rodbusters, also known as reinforcing ironworkers, use reinforcing bar to build structures according to a specific design. Reinforcing Ironworkers tie reinforcing bar together using tie wire to assemble structures.

The P-140 Piranha Ironworker has the highest ranking in its class. It is capable of performing all functions that are expected of ironworkers, including bending, punching and notching. The versatility of this Ironworker will increase shop productivity as it allows for many tasks to be completed quickly and easily.